This year, Stainless Steel Coatings, Inc. (SSC), the Makers of STEEL-IT® Brand Coatings, celebrates its 50th year in business. Proudly made in the USA since 1974, STEEL-IT is a unique line of high-performance coatings packed full of custom-engineered, high-grade 316L stainless steel flake. When applied, either by spray, brush, or roller, the microscopic flakes align horizontally and pack densely to form a barrier that’s practically impervious to the destructive effects of corrosion and the battering that metals endure in extreme physical and chemical environments. As one of SSC’s customers exclaimed, “Using STEEL-IT is like applying stainless steel armor!”

“Our team is thrilled to have reached our 50th year,” commented Michael Faigen, SSC’s President & CEO. “It’s truly a joy to see how we’ve grown and matured as a company with products that continue to offer a level of protection that delights our customers. In a few weeks, we’re kicking off this special year by launching our new STEEL-IT 1006 Charcoal. It will accompany our other single-component polyurethane coatings such as Steel Gray and Black, all of which are weldable. And that’s just the start! We have more exciting news to come during the remainder of the year and beyond.”

Prized worldwide for its superior performance and ease-of-use, STEEL-IT has earned its place in myriad applications across diverse industries. These include food processing equipment and facilities where USDA-compliance is a must, racing and automotive, boating, construction, architecture, aerospace, agriculture, and machinery and industrial maintenance. “In short,” Mr. Faigen said, “STEEL-IT’s an exceptional choice wherever there’s metal that rusts!”

“Multinational corporations have relied on STEEL-IT for decades, but we’re also finding that STEEL-IT’s become a favorite among Do-It-Yourselfers. They see the value of coating their vehicles, fences, gates, patio furniture, metal doors, and so many other items around the home, even if they live in a salt-air environment on or near the ocean,” Mr. Faigen added.

“Like race teams who compete in Baja California, the Bonneville Salt Flats, and other harsh, corrosive environments, our customers know that STEEL-IT doesn’t care about salt; STEEL-IT just endures! They also appreciate that STEEL-IT can last for years before needing touch up: removing the coating and starting fresh is rarely, if ever, necessary. Other coatings and paints may cost less initially but must be reapplied every three months, six months, or every year when they fail. This means that STEEL-IT, when considering its total cost of ownership, is less expensive since our customers don’t have to buy an inferior coating again and again to redo a job.”

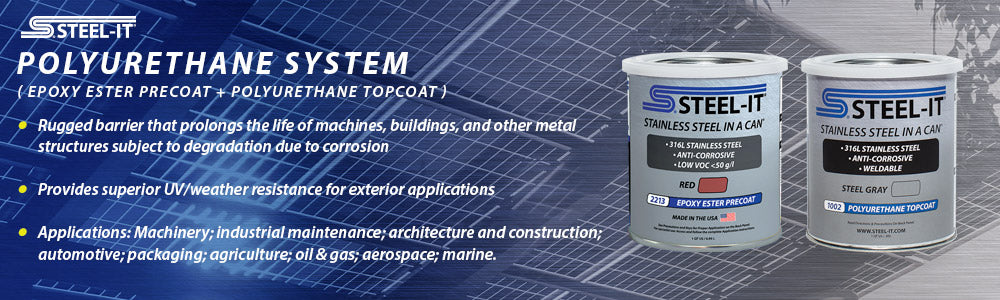

To complement its single-component, air-dry line of polyurethane topcoats, SSC offers an epoxy ester precoat that contains 316L flake and other anticorrosives. This Polyurethane System of precoat and topcoat dramatically extends the life of steel, iron, and even grades of stainless steel that corrode.

SSC also manufactures the STEEL-IT Epoxy System, consisting of a 2-part precoat and 2-part topcoat.

In addition, SSC offers a single-component High Temp and Corrosion-Resistant coating that withstands constant temperatures up to 1000 oF and spikes up to 1200 oF.

STEEL-IT’s High Temp Coating, like its Polyurethane and Epoxy Ester coatings, are available in handy aerosols, quarts, and gallons, and in larger containers as a special order. The Epoxy System’s precoat and topcoat are also available in quarts and gallons, and in other package sizes upon request.

We are proud to celebrate this milestone with our customers, employees, and STEEL-IT partners around the globe. Cheers to another 50 years!